In keeping with my waste-not-want-not leanings, and because my friends are still giving me their worn-out jeans (Yay! Keep it up!), the perfect material was obvious: recycled denim! I had also recently bought a book at a silent auction, "The New Sampler Quilt" by Diana Leone, and making sampler blocks for the chair covers seemed like a project I might be able to finish in a reasonable time (where "reasonable" is defined as "less time than the still-unfinished Jeans Circle Quilt from Hell").

The Jeans

For my six chairs, I used the legs of 10 pairs of adult jeans. Four pairs of varying colors (black, dark blue, medium blue, light blue) went to form the quilt blocks. Then I used one pair of legs for the surrounding sections on each chair.

The jeans pocket sections went to the middle school for a group making bags for a school project.

Finding the Grain

Quilt tops work better if the pieces are cut on the grain of the fabric. The grain of reused jeans isn't always obvious because of the diagonal pattern of the denim weave, so I found the grain by pulling off thread after thread (fraying the denim) until I had a straight edge I could work from. Fortunately I had plenty of excess on the jeans legs.

The Squares

Each chair has a different classic quilt square design. I did Wheel, Spools, Ohio Star, Monkey Wrench, King's X, and Card Trick (the hands-down favorite of the household--it's the one behind the dog).

I made templates from the patterns in the sampler book, traced with kids' washable markers and cut them out, and machine pieced them following the instructions in the book.

Once the squares were pieced, I sewed on the fabric from a pair of legs around the square to make the background. I washed the covers after that to get rid of the washable marker.

Quilting

I used batting left over from a previous project. For the quilt backing, I reused six small flannel receiving blankets (complete with Pooh or teddy bear pictures!) that I had left from when my two kids were newborn babies. This would never be visible, but it wouldn't hurt to have something sturdy but soft wrapped around the padding and the wooden seat bases.

I machine quilted the three layers "in the ditch" along the seam lines between the square design pieces so the sewing wouldn't be very visible.

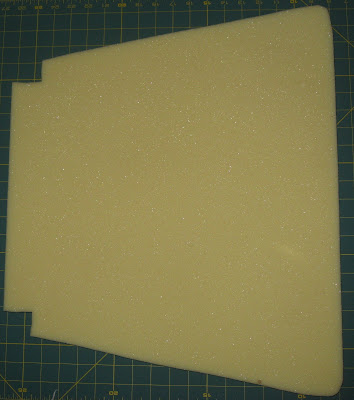

House of Foam

Padding matters. I got a couple of different "chair-sized" pieces of padding at the local fabric/crafts store. These were two inches thick. One was Airtex High Density Foam. The other was Poly-Fil NU-Foam, which is a compressed polyester fiber pad. Unfortunately they were too small for my chairs, but my family sat on them for a week or so to try them out. I found they were too thick to fit well under the backs of the chairs, but they weren't firm enough. When we sat on them, we'd go right down to the wood surface beneath.

I went to a place called House of Foam in Palo Alto, CA. The proprietor suggested 1" thick high resilience (HR) foam, which he said is the usual one he sells for dining room chairs. It cost about $12 per chair (just slightly more than the same amount of the other padding types would have cost), but as his website says, "Generally the firmer the foam, the longer its firmness will last, and the more expensive it is." However, what I got from House of Foam was definitely the right stuff. They even cut it to shape and glued it onto the the chair seats for me while I ate lunch across the street, making it well worth it for me to go to such a specialty shop.

Putting It Together

I cut off the excess from the quilted covers, then I sprayed the covers with a coat of Scotchgard in the (probably vain) hope that the covers would stay cleaner longer. I used a staple gun to attach the cover over the foam and around to the bottom of the wooden seat pieces. Each seat was then attached to the chair legs and back with four screws, so that part was easy.

Here is the finished set of chairs.

Here is the finished set of chairs.

New Beginning and the End

Interestingly, when I removed the previous covers from the wood, I found that these chairs had been recovered at least twice before (old staples and tacks, shreds of two other fabrics). It feels kind of nice to be carrying on a tradition of reuse, and not just throwing something away because it was old. I did, however, grit my teeth and throw out the old cotton padding and fabric covers. They had done their share of service.

Gratuitous Dog Pictures

I managed to sneak in one or two blog entries without dog pictures, but this entry required a lot of pictures, and Lacey now comes running if she even hears the camera turn on.

She's a big help!

She's a big help!

She looks like this chair is made for her.

After all, since I have to let my kids sit on these chairs, why not the dog? The kids are often messier!